- Cold formed steel framing details header how to#

- Cold formed steel framing details header windows#

Load-bearing requirements of any items attached to the studs, and whether the studs meet the minimum integrity to support them.

These are a few examples of the types of questions one might see on a framing inspection: Of course, there are countless specific parameters that can govern load-balancing standards depending on the purpose of the structure, but all are held against the standard of avoiding collapse. In some structures, jacks are replaced by header hangersįraming inspections concentrate heavily on wall studs since they make up the most practical part of the structure, and the focus is always on load-balancing. Jack - a stud that runs from the base to the underside of a horizontal fixture, like the header atop a door frame, usually to help the king stud support the load.Cripples are considered synonymous with saddles and sills in most builder’s lexicons.

Cripple - A section of wall stud that is shorter than the length of the wall, such as a stud between the bottom of a window sill and the sole plate.

However, since king studs frame the outside of openings like windows and doors, its surface has more function than a standard stud, which is only used for support.

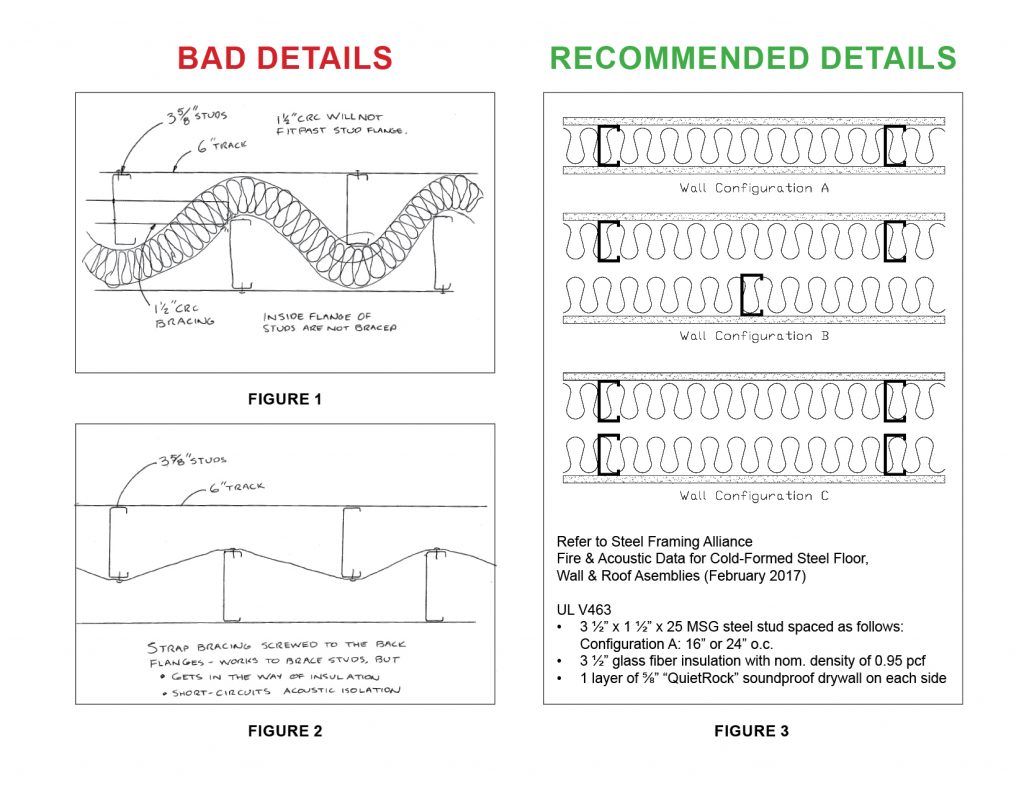

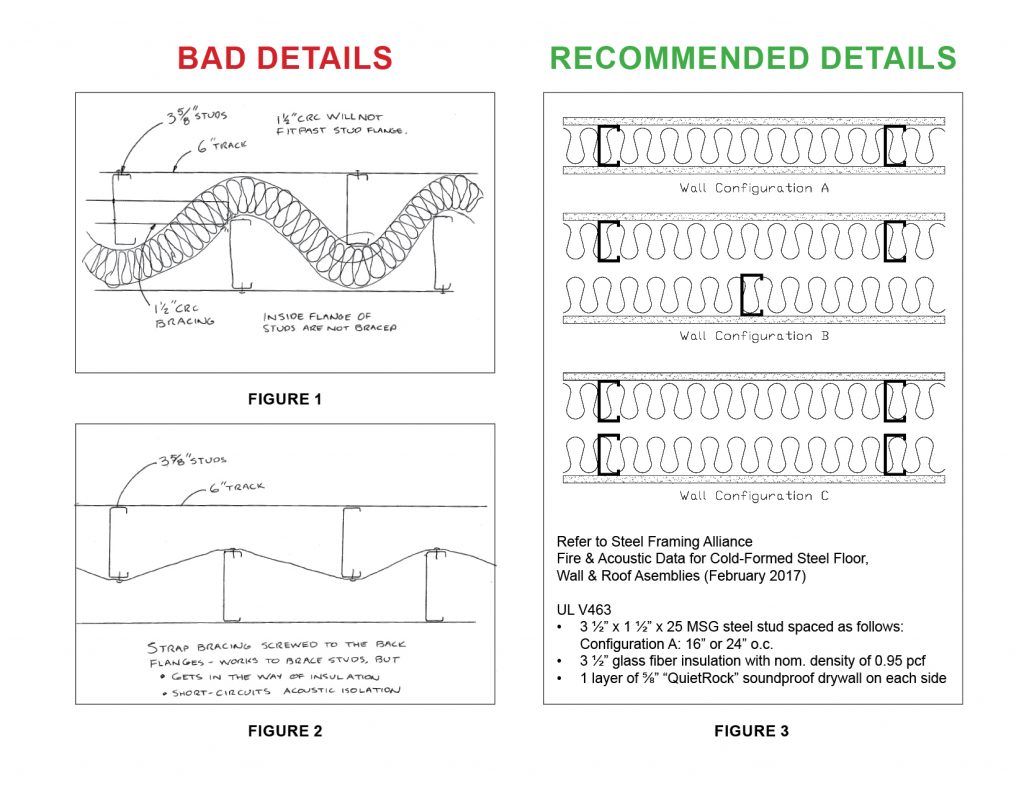

King - This is essentially a standard top-to-bottom wall stud. The following is a brief list of conventional metal studs ( cold formed steel studs) and their purpose: Wall studs also make a good base for screws and nails, so both builders and occupants often use devices called stud finders to locate them so they can hang items like light fixtures and picture frames. Conversely, posts fastened to these studs generally contain the horizontal structures like sill plates and headers. Their load-balancing tasks include the wall plates which create an actual wall from the empty space between frames, as well as the various members a wall may contain, such as doors, windows, and insulation. Studs join with posts to distribute the framework structural loads. Wall studs are vertical framing components–often made of wood, but increasingly metal ( cold formed steel studs framing)–that connect with posts, forming the vertical support of a wall. As such, intermediate readers can skip the first paragraph, which explains what wall studs actually are for clarity. For more information, visit article is intended to provide a more cohesive general reference to wall studs and their various uses than those currently available, as each tends to lean toward a particular type. īuildSteel is a cold-formed steel framing resource center for building professionals, providing resources, education, and complimentary project assistance related to the use of cold-formed steel framing in low and mid-rise and multi-family construction projects. “Cold-Formed Steel Framing: Engineering the Details of Your Next Project” can be downloaded at. How to address seemingly minor construction details that can have a significant impact on a project. How exterior continuous insulation requirements affect field integrations. How to engineer subfloors for better sound attenuation. “Beyond the major driving factors such as budget and timeline, building professionals must address the technical specifications that allow them to construct a building that’s safe, durable, structurally sound, and aesthetically appealing.” “The success of a construction project often comes down to the details,” said Dan Snyder, director of BuildSteel. Washington, DC - BuildSteel, an alliance of steel and construction industry organizations, announces the release of “Cold-Formed Steel Framing: Engineering the Details of Your Next Project,” an e-book exploring several technical aspects of designing and engineering cold-formed steel framing for successful projects. Cold-Formed Steel Framing Engineering Guide Available

0 kommentar(er)

0 kommentar(er)